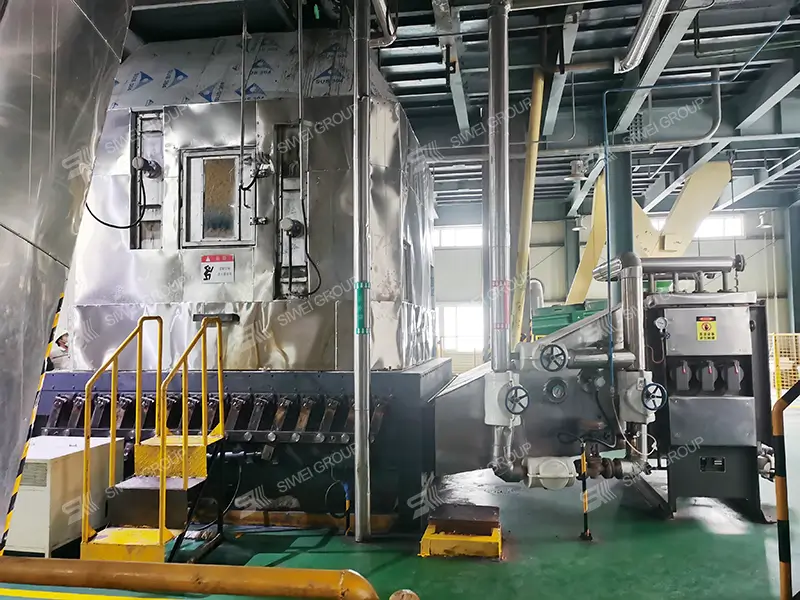

TZJ type conditioning tower is one of the main equipment widely used in the pretreatment process of large-scale oil production enterprises. It mainly performs conditioning treatment on soybeans and other oilseeds after initial cleaning to make their physical properties more suitable for subsequent processing. The conditioning tower integrates conditioning, softening, water removal and drying, which not only helps ensure the quality of oilseeds, but also simplifies the production process. During the conditioning process, on the one hand, the oilseed is heated to 60°C to 70°C to soften the oilseed to facilitate subsequent flaking. At the same time, the internal structure of the oilseed can be evenly distributed, the moisture inside and outside the oilseed can be evenly distributed and a certain amount of moisture in the oilseed can be removed.