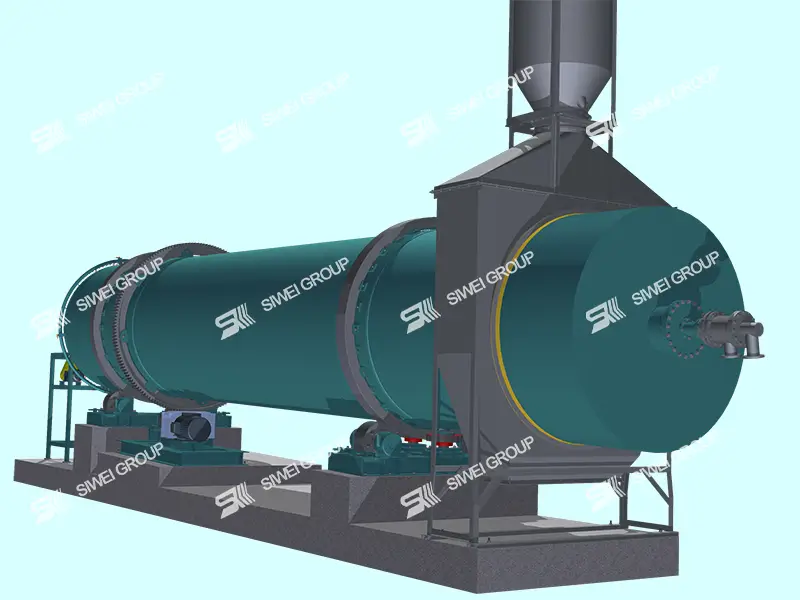

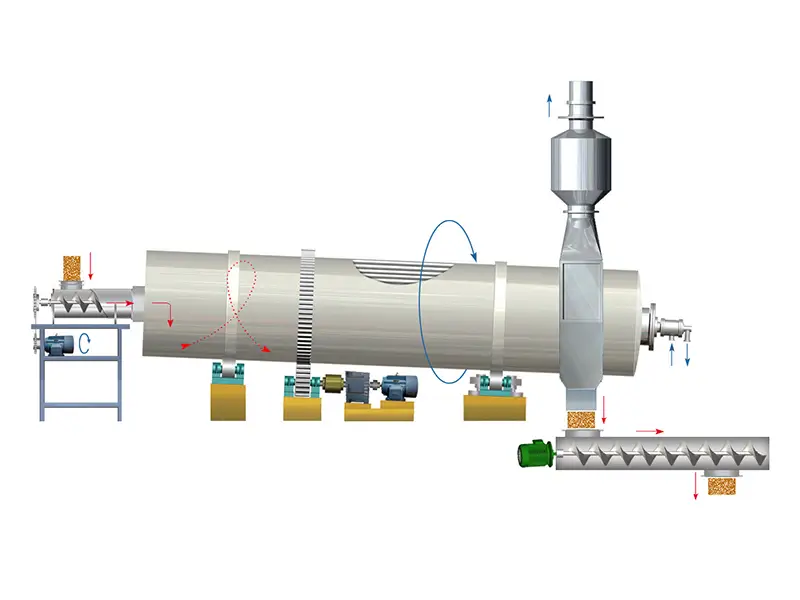

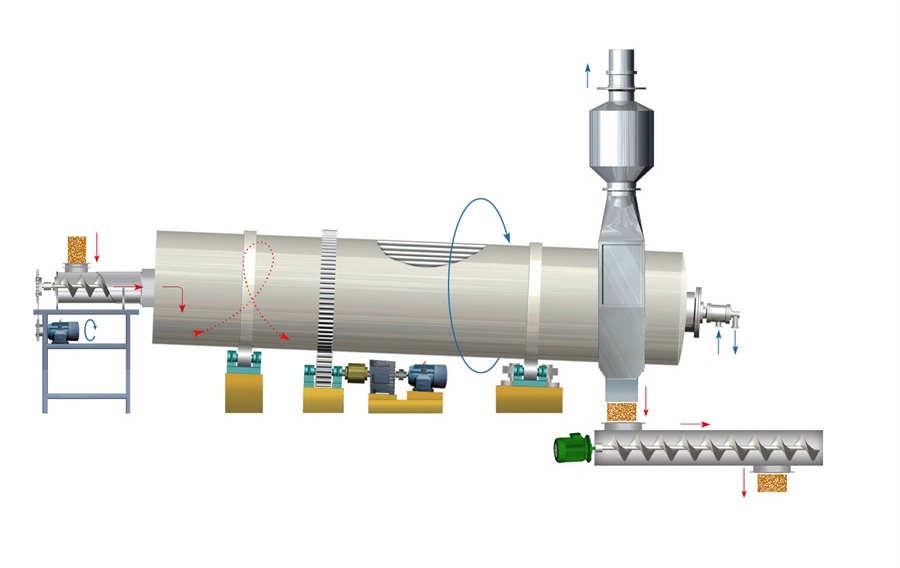

YGZJ Horizontal Cooker is a patented product of our company, which is suitable for 100~3000 tons/day oil pressing plant and oil extraction plant, and is mainly used for softening and drying oilseeds, and it can improve the plasticity of raw materials, so as to make flake rolled out by flaker be thin but not crushed, and thus to improve the effect of cooking, pressing, and extraction.

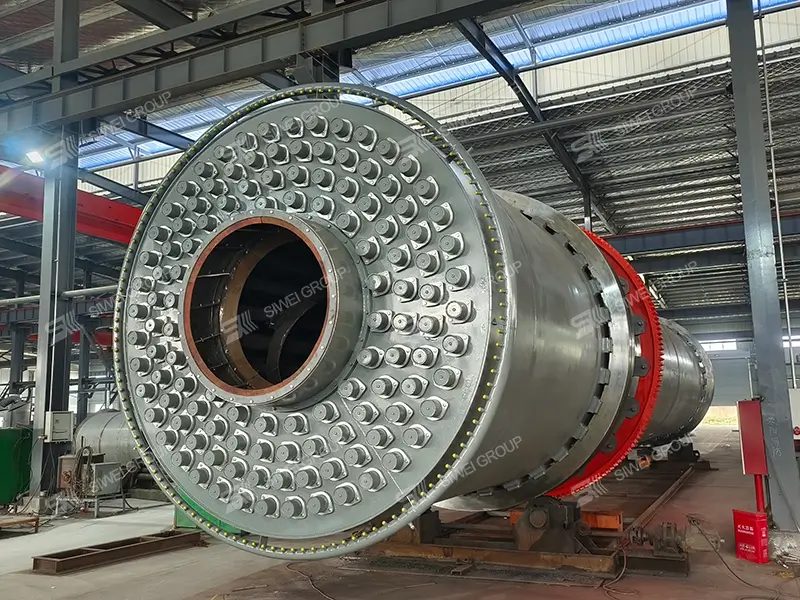

The raw material is conveyed into the drum through the feeding winch, because the drum with inclined angle is equipped with heating column, and the column is passed with steam, so the material is heated and softened at the same time when it is turning and advancing along with the drum.

Machine Production capacity: 1500T / D ~ 3000T / D