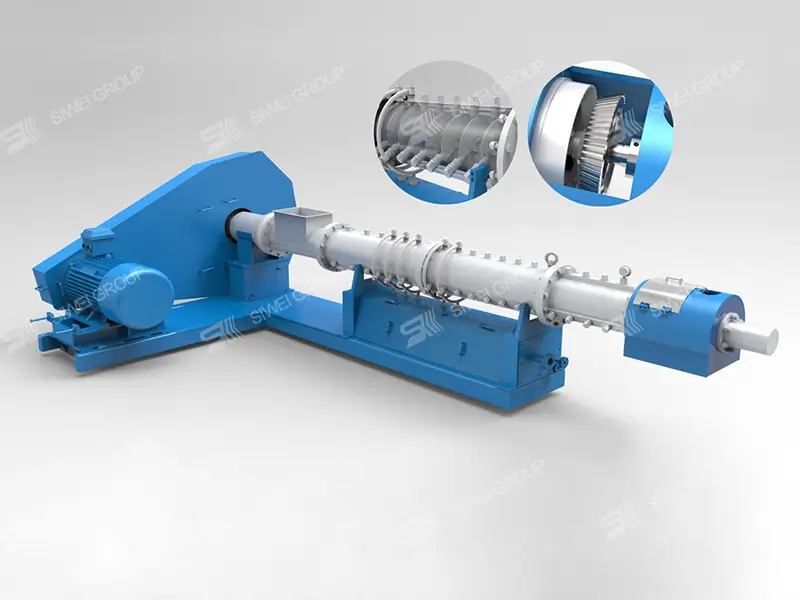

Oilseeds in the extruder by extrusion, kneading, shear, pressure and other mechanical effects, as well as sprayed into the steam moist heat, friction heating effect and a series of physical and chemical effects, the oil cellular organisation is completely destroyed, the enzymes in the oilseeds is blunted, from the outlet of the extruder, high temperature, high pressure of the material instantly from high pressure into atmospheric pressure, resulting in moisture rapidly released from the material organisation. The material is then expanded and shaped, thus obtaining loose and high strength extruded material.

Main feature

- Improve the production capacity of extractor. As the volume weight of extruded material increases by 40-50% compared with that of raw flakes, the capacity of extractor and DTDC is increased.

- Improve the extraction speed and shorten the extraction time. Due to the complete destruction of the cellular organisation of the extruded material, the porosity of the extruded material is improved, and the permeability of the solvent and mixed oil through the material layer is improved.

- Wet meal solubility reduction, reducing the load of wet meal desolvation. Due to the permeability of the extruded material and good extraction, wet meal solubility can be reduced to about 20%, reducing the load of wet meal desolvation and solvent recovery load, thus reducing the steam consumption of wet meal desolvation.

- Concentration of mixed oil increased, reducing the load of mixed oil evaporation, reducing the steam consumption of mixed oil evaporation process.

- Enzyme in the oilseed is passivated, which improves the quality of the crude extracted oil. The enzymes and anti-nutritional factors in the oil are passivated in the process of extrusion, avoiding the influence of fat oxidase and phospholipase on the phospholipids in the oil, decreasing the content of non-hydrated phospholipids in the crude extracted oil and increasing the total phospholipids in the crude extracted oil, which can effectively improve the efficiency of oil refining, improve the product quality of the oil and enhance the yield of phospholipid by-products and the quality of phospholipids in the process of hydration and degumming.

- Reduced energy consumption in the extraction production process. Due to the increase of mixed oil concentration and the decrease of wet meal solubility, the solvent loss in the extraction production process can be effectively reduced. Due to the increase in production capacity, all kinds of consumption consumption and production cost in the production process can be reduced.