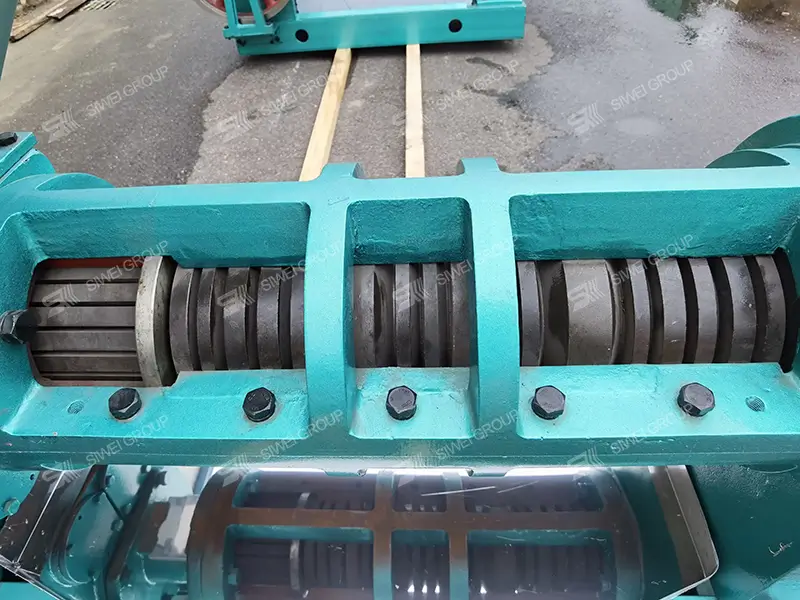

The Screw oil press independently developed and produced by Siwei Group has a daily processing capacity from 0.2 tons to 20 tons. Screw oil press is a common oil extraction equipment, suitable for extracting various vegetable oils. The screw oil press pushes the oilseed from the feed port into the oil pressing chamber through the spiral groove on the spiral shaft with gradually increasing pitch and separates the oil in the oilseed through the pressing screw in the spiral groove. The screw oil press developed by our company has a simple structure and high extraction efficiency. The residual oil in the cake is about 6%.

Our oil presses are divided into three series:

- Oil press series

- Oil press with temperature control series

- Oil press with temperature control and filter series

Filtration equipment and automatic temperature control systems can be installed according to your production needs, making them more flexible and cost-effective.