For coconut oil production line, our company adopts physical pressing to make oil, and also can adopt extraction to extract oil. For coconut oil production line, our company can provide a full range of service according to customer needs, including oil plant planning, engineering design, process flow, technology selection, installation and commissioning, equipment configuration and expansion and upgrading of oil plant.

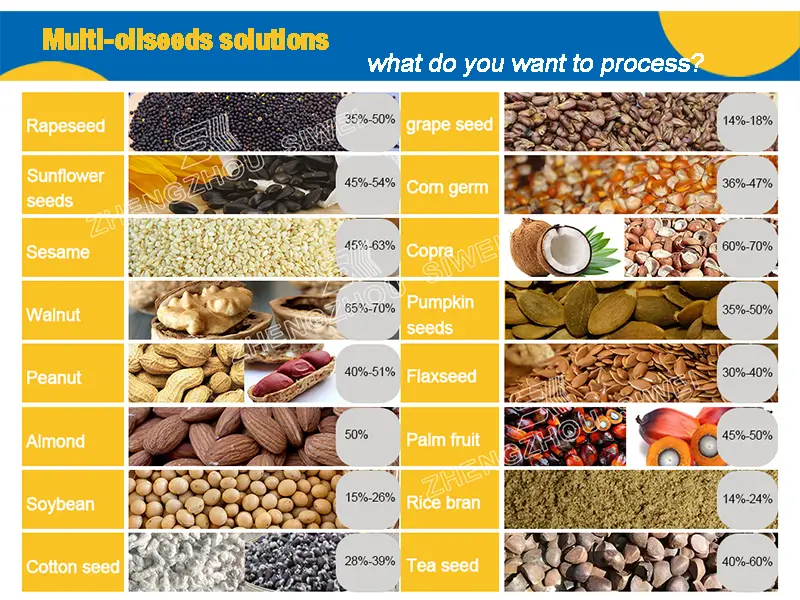

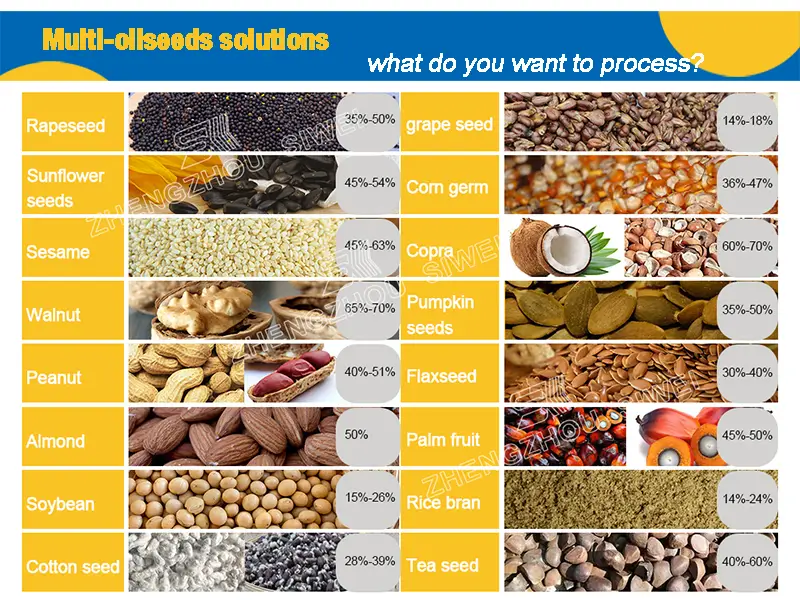

What can we do for oil seeds?

Our process

- Advanced copra pressing process, including Copra Cleaning → Drying → Crushing → Softening → Pre-pressing → Second pressing → Filtration, etc. After the second pressing, the residual oil in the cake will be to about 5%.

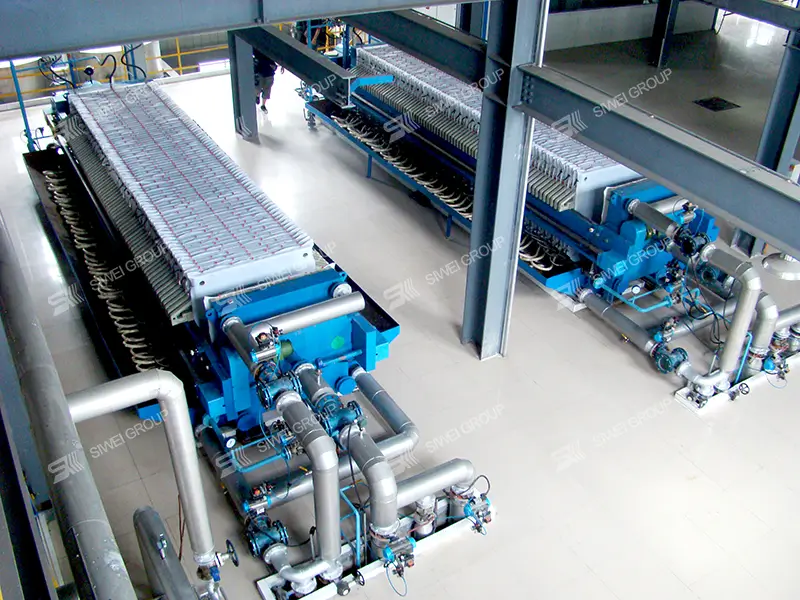

- Solvent extraction process is used to increase the oil extraction rate, reduce the production cost and get the maximum benefit.

- The coconut oil refining is mainly done by physical refining process, which can be efficiently deodorised and further contribute to the improvement of oil quality by removing impurity, odour and free fatty acid.

-

-

Oilseeds Crusher

-

-

Oil extraction machine

Our technology

- Advanced automation and intelligent control technology for monitoring the whole production process to ensure product stability and high efficiency of the production line.

- We build oil plant with low energy consumption and low waste emission environmental protection technology, which is in line with international environmental protection standards.

- The process design takes full account of energy saving and environmental protection, controlling dust emissions, heat recovery and reducing production energy consumption. The process and automation are efficiently integrated to reduce the customer’s labour input and improve the product index and stability.