Cottonseed oil is oil squeezed from cottonseed. It is divided into pressed cottonseed oil and extracted cottonseed oil. The color is darker red than other oils. Only refined cottonseed oil can be consumed by humans.

Siwei Group can provide full range of cottonseed oil solutions according to your needs, including site planning, engineering design, equipment manufacturing, installation and commissioning, as well as oil plant expansion and upgrades, etc.

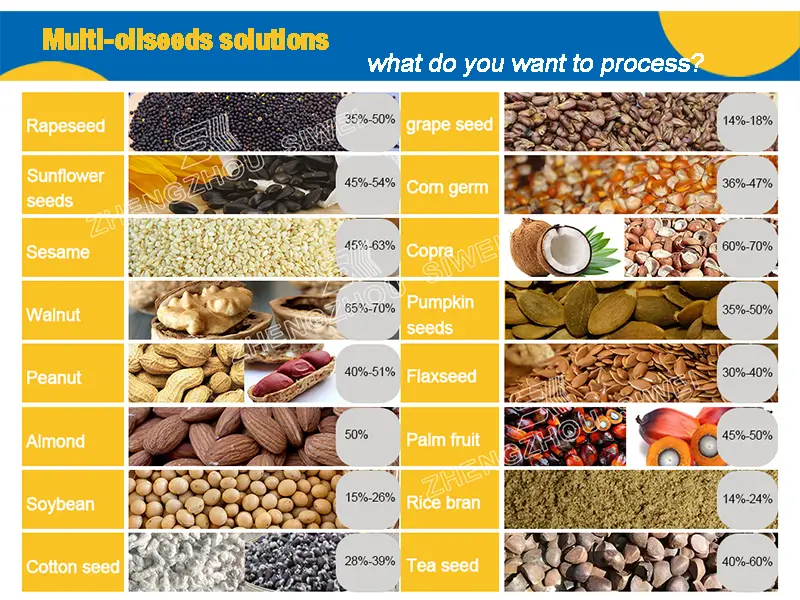

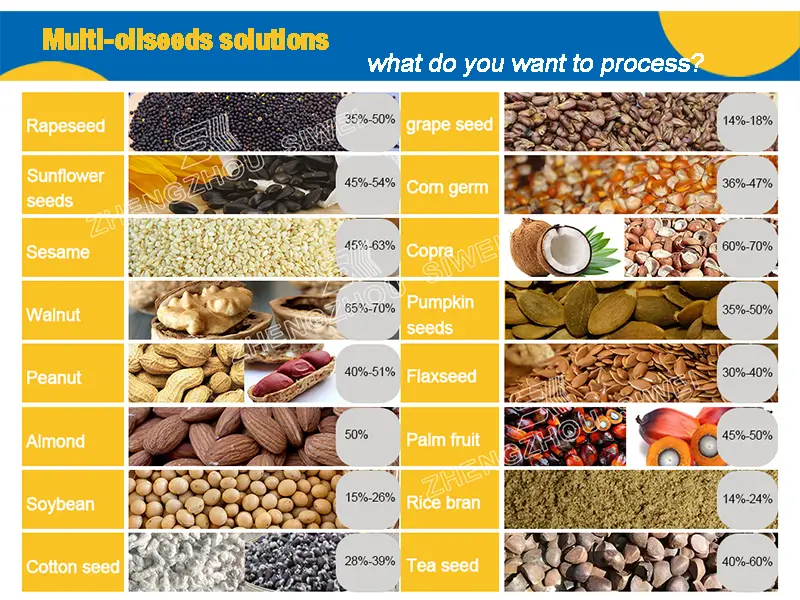

What can we do for oil seeds?

Our Process

- Cottonseed pretreatment process: delinting → cleaning → shelling → conditioning → flaking→ extruding → cooling

- After the cotton kernel is conditioned and flaked, the oil extraction rate and crude oil quality will be greatly improved. Subsequently, extruding + extraction or pre-pressing + extraction can be selected according to customer needs.

- The cottonseed meal we produce contains low gossypol content and light color, and the protein content can be adjusted according to customer needs.

- Cottonseed oil refining can be divided into batch refining, semi-continuous refining and continuous refining according to the capacity of the production line. We will choose the appropriate cottonseed oil refining production line according to your actual situation.

-

-

Oilseeds cleaning

-

-

Crusher

Our Technology

- Siwei Group’s most advanced automation and intelligent control technology is used to monitor the entire production process to ensure product stability and high efficiency of the production line.

- The efficient integration of technology and automation reduces customer labor input and improves product indicators and stability.

-

-

Oilseeds cooking

-

-

Big oil press