Undertake 500T/D-10000T/D oilseeds inactivation project.

We provide tailor-made service solutions for customer, including site planning, engineering design, equipment manufacturing, installation and commissioning, as well as the expansion and upgrading of oil plant.

2. Our process

- In order to prevent the introduction of foreign hazardous animals and plant, germs, pests, weed seeds and other harmful organisms from abroad, and to protect the domestic ecological environment and people’s health, the State Entry-Exit Inspection and Quarantine stipulates that all imported oilseeds and their appurtenances must undergo an inactivation treatment before they can be brought into the domestic market.

- Our company undertakes inactivation projects for all kinds of oilseeds. Our design process integrates automation, energy saving and environmental protection, and the advanced active maintenance system and intelligent control system bring great convenience to production. The programme is stable in operation, intelligent and simple in operation, stable and precise in controlling the main points of the process, and convenient in management.

Our technology

Advanced automation and intelligent control technologies are used to monitor the entire production process, ensuring product stability and high line efficiency.

Zhengzhou Siwei provides oilseeds inactivation equipment with the following features:

- Energy saving and environmental protection, inactivation thoroughly;

- High degree of automation and control, saving manpower;

- Advanced technology, reasonable layout, stable equipment;

- Maintain the inherent form of the material ensures flexibility in product trading;

- Short engineering and fabrication time, fast project implementation and short payback period.

Our equipment

- The main equipment for the production of oilseeds inactivation project include: cleaning equipment, inactivation equipment, etc.

- We customise our equipment according to customer-specific needs to suit different processing capability and process requirement.

- High-performance, high-quality equipment and attentive service ensure the long-term stable operation of the equipment.

-

-

Oilseeds inactivation tower

-

-

Oilseeds inactivation tower

-

-

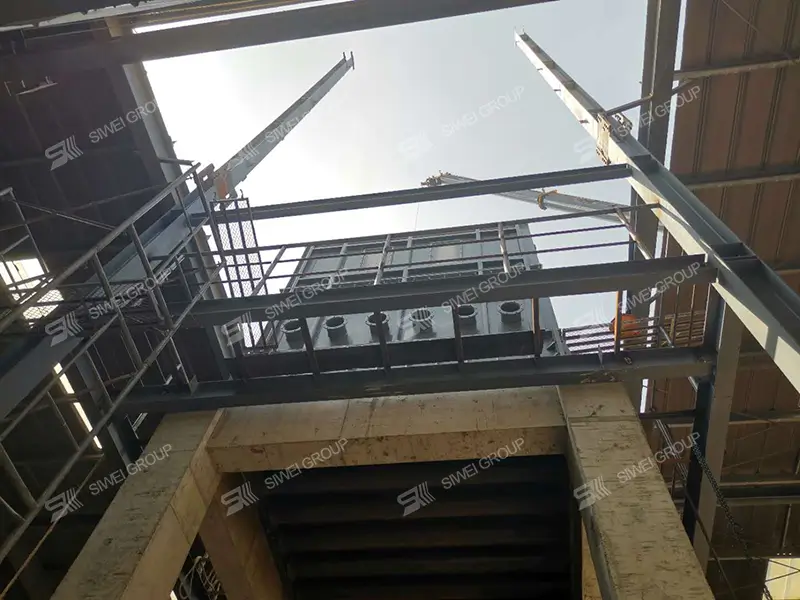

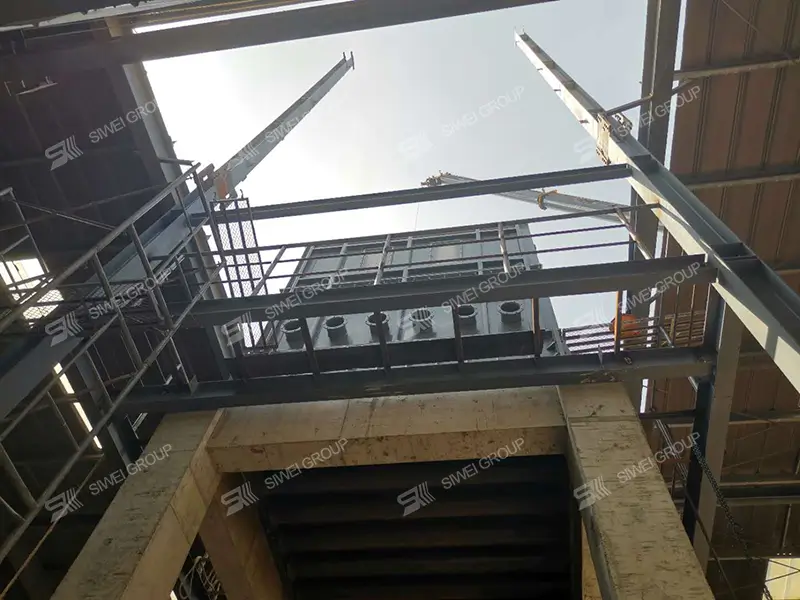

Oilseeds inactivation tower works

-

-

Oilseeds inactivation tower works