For palm kernel production line, our company can provide a full range of services according to customer needs, including oil plant planning, engineering design, process flow, technology selection, equipment configuration and after-sales service. The following is a detailed description:

1. Business scope

Undertake 1T/D-200T/D palm kernel pressing production line

We provide tailor-made service solutions for customer, including site planning, engineering design, equipment manufacturing, installation and commissioning, as well as the expansion and upgrading of oil plant.

2. Our process

Advanced palm kernel pressing process, including Palm Kernel Cleaning → Crushing →Flaking → Cooking → Pressing → Filtration, etc.

Crude palm kernel oil contains some impurity, such as colloidal impurity, free fatty acids, pigments, off-flavour substances, etc., which can be further removed through the refining process to further improve the quality of the oil and facilitate long-term storage.

3. Our technology

Advanced automation and intelligent control technology for monitoring the whole production process to ensure product stability and high efficiency of the production line.

We build oil plant with low energy consumption and low waste emission environmental protection technology, which is in line with international environmental protection standards.

The process design takes full account of energy saving and environmental protection, controlling dust emissions, heat recovery and reducing production energy consumption. The process and automation are efficiently integrated to reduce the customer’s labour input and improve the product index and stability.

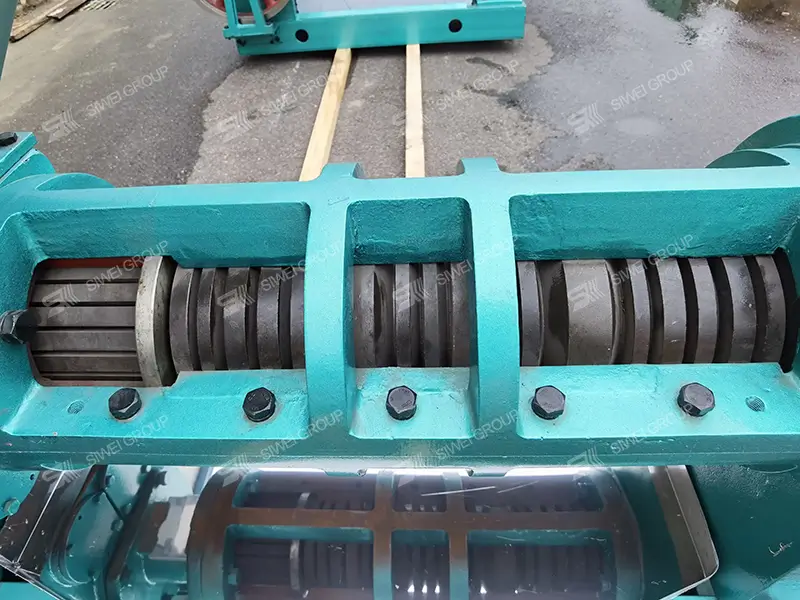

4. Our equipment

The main equipments for palm kernel oil production are: cleaning equipment, crusher, flaker, press, filter, refining equipment as well as automatic filling and packing equipment.

We customise our equipment according to customer-specific needs to suit different processing capability and process requirement.

High-performance, high-quality equipment and attentive service ensure the long-term stable operation of the equipment.

5. Our service

(1) Provide project consultancy and feasibility analysis. Help client assess the economic benefits and market potential of projects.

(2) Provide engineering design and project management services to ensure that the project is completed on time and on budget.

(3) Provide installation and commissioning and staff training to ensure that the customer’s staff can effectively operate the production line and understand the necessary maintenance knowledge.

(4) Provide after-sales service and technical support, including but not limited to regular maintenance, troubleshooting and technical upgrades.

We provide comprehensive support to our customer in the construction of palm kernel oil production line. From project planning to every stage of production line operation, we ensure that our customers can achieve efficient, stable and sustainable production operations. Through continuous technological innovation and service optimisation, our goal is to help our customer increase production capacity, reduce cost and improve the market competitiveness of the final product.