We provide customized services for customers, including cold-pressed peanut oil, fragrant peanut oil and strong-flavor peanut oil production lines. We provide site planning, engineering design, equipment manufacturing, installation and commissioning as well as the expansion and upgrading of oil plants.

-

-

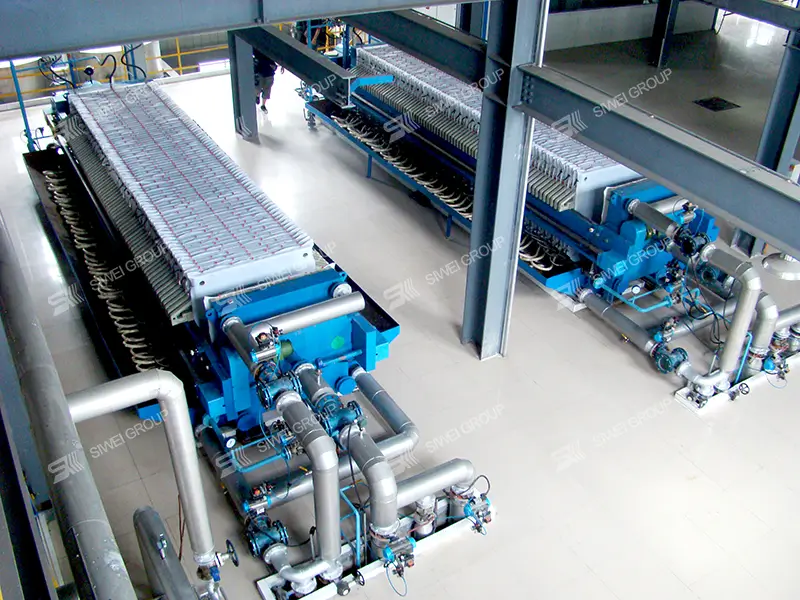

Oil extraction machine

-

-

Oil extraction machine

Our Process

- Advanced peanut pretreatment and pressing process, including sunflower seed cleaning – crushing – rolling – steaming and frying – pressing – three-stage filtration, etc., to maximize the oil yield.

- Solvent leaching process is used to improve the oil extraction rate, reduce production costs, and obtain maximum benefits.

- Physical refining and chemical refining processes can be selected to improve oil quality and remove impurities and free fatty acid.

-

-

Shelling machine

-

-

Oilseeds cleaning

Our Technology

- Advanced automation and intelligent control technology are used to monitor the entire production process to ensure product stability and high efficiency of the production line.

- The oil plants we build are environmentally friendly technologies with low energy consumption, low waste emissions and comply with international environmental protection standards.

- The process design fully considers energy saving and environmental protection, controlling dust emissions, recovering heat energy and reducing production energy consumption, etc. The efficient integration of technology and automation reduces customer labor input and improves product indicators and stability.

-

-

Crusher

-

-

Flaker