Siwei group successfully developed rice bran extruder, effectively solved the problem of freshness and storage for rice bran, make rice bran refining yield increase, cost reduction, comprehensively enhance the value of rice bran, greatly improve the economic benefits of feeding grade rice bran, rice oil processing enterprises. After processing, the flavour of rice bran is improved, also can be used as food grade rice bran. Rice bran extruder is successfully applied in international famous enterprises such as Yihai Kerry, and achieved good results.

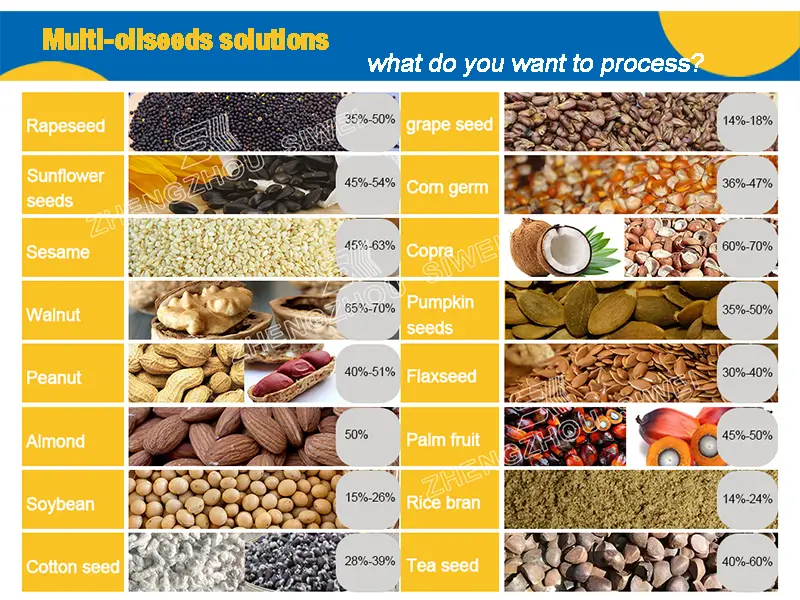

The lipolytic enzyme in rice bran will lead to the rancidity of rice bran and reduce the yield of oil. For rice bran oil production line, We provide tailor-made service solutions for customer, including site planning, engineering design, equipment manufacturing, installation and commissioning, as well as the expansion and upgrading of oil plant.

-

-

Cleaning

-

-

Corn germ extruder

Our process

- Advanced rice bran pre-treatment process, including Rice Bran Cleaning → Cooking → Expanding → Drying, etc., followed by the extraction plant to maximise the oil yield.

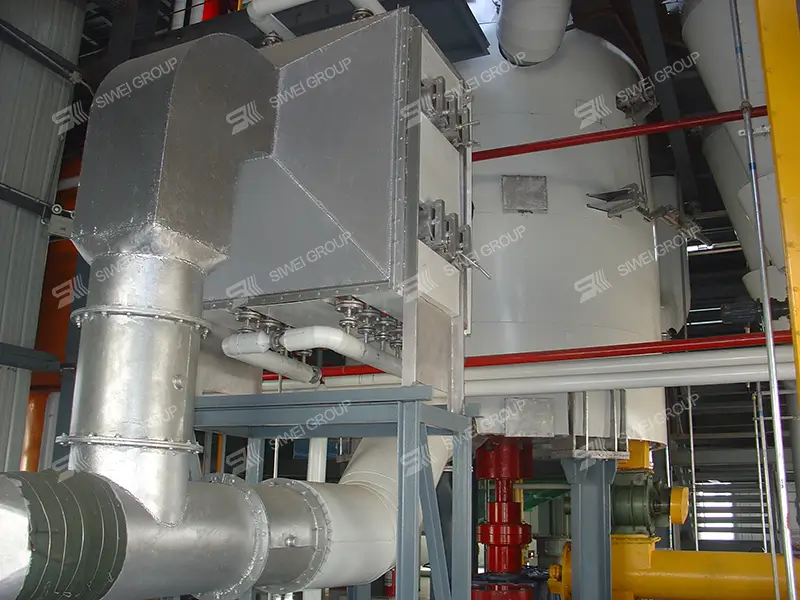

- A solvent extraction process used to increase oil extraction rates, reduce production cost and maximise benefit.

- Rice bran oil is difficult to refine because of its high acid value, the rice bran oil refining process researched and developed by our company contains deacidification, degumming, bextractoring, deodorization and dewaxing section, which can reduce the acid value of rice bran oil to the maximum extent, retain its original nutrients, improve the flavour and taste, and prolong the storage time.

-

-

solvent tank

-

-

Oil solvent extraction

Our technology

- Advanced automation and intelligent control technology for monitoring the whole production process to ensure product stability and high efficiency of the production line.

- We build oil plant with low energy consumption and low waste emission environmental protection technology, which is in line with international environmental protection standards.

- The process design takes full account of energy saving and environmental protection, controlling dust emissions, heat recovery and reducing production energy consumption. The process and automation are efficiently integrated to reduce the customer’s labour input and improve the product index and stability.