For the sunflower seed oil production line, our company can provide comprehensive services tailored to customer needs, including oil plant planning, engineering design, process flow, technology selection, equipment configuration and after-sales service, etc.

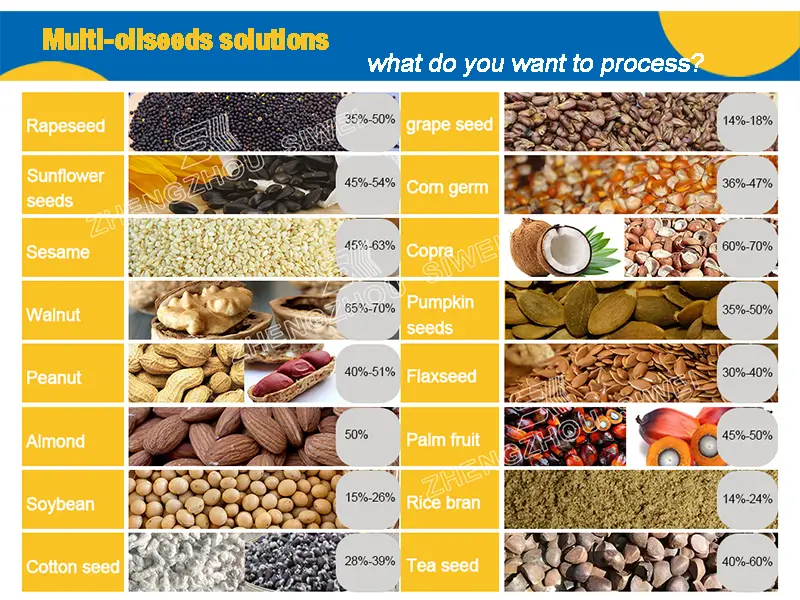

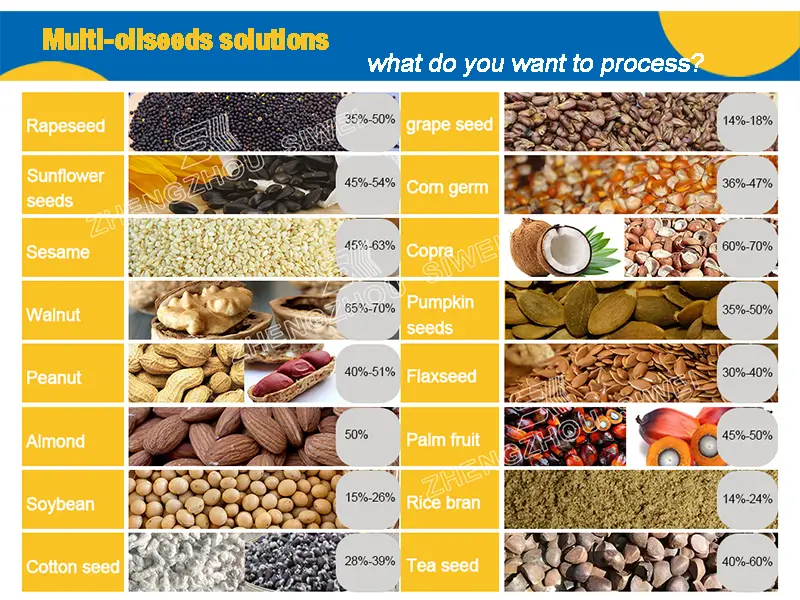

What can we do for oil seeds?

Oilseeds

Our Process

- The production of sunflower seed oil adopts processes such as pretreatment, pressing, solvent extraction and refining, scientifically controlling the physical changes during the oil production process to increase oil yield and reduce the residual oil rate in meal.

- Our advanced sunflower seed pretreatment and pressing process includes seed cleaning → shelling→ conditioning → flaking → cooking → pressing → three-stage To enhance the flavor of sunflower seed oil, a unique roasting and pressing process is used to produce aromatic sunflower seed oil.

- The solvent extraction process is used to increase oil extraction rate, reduce production costs and obtain maximum benefits.

- The crude oil obtained through solvent extraction undergoes refining processes such as degumming, deacidification, bleaching, deodorization and dewaxing to produce the refined sunflower seed oil.

-

-

Crusher

-

-

Oilseeds cooking

Our Technology

- Advanced automation and intelligent control technologies are utilized to monitor the entire production process, ensuring product stability and the high efficiency of the production line.

- The Process and automation are efficiently integrated to reduce labor input from our customers and to enhance product quality and stability.

-

-

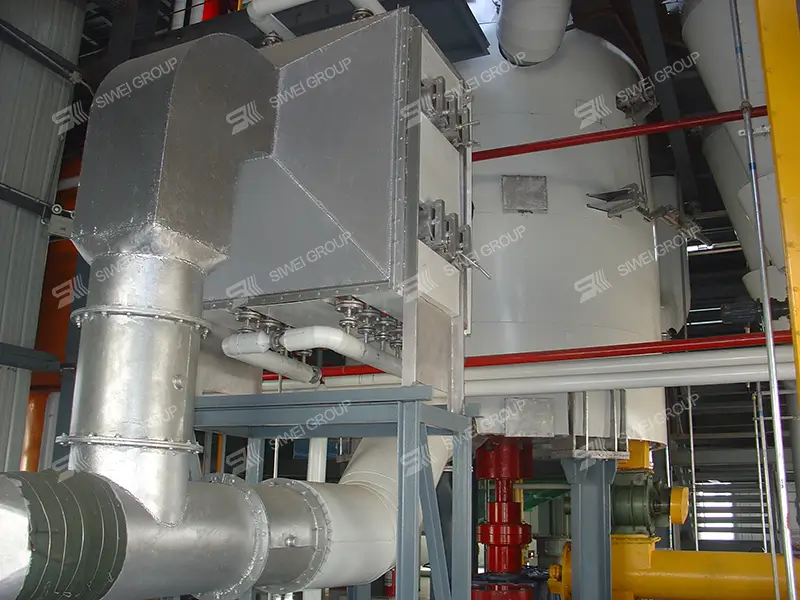

Ring oil extraction

-